Digital Dot Gauge Quantifying Paint Defects with AI

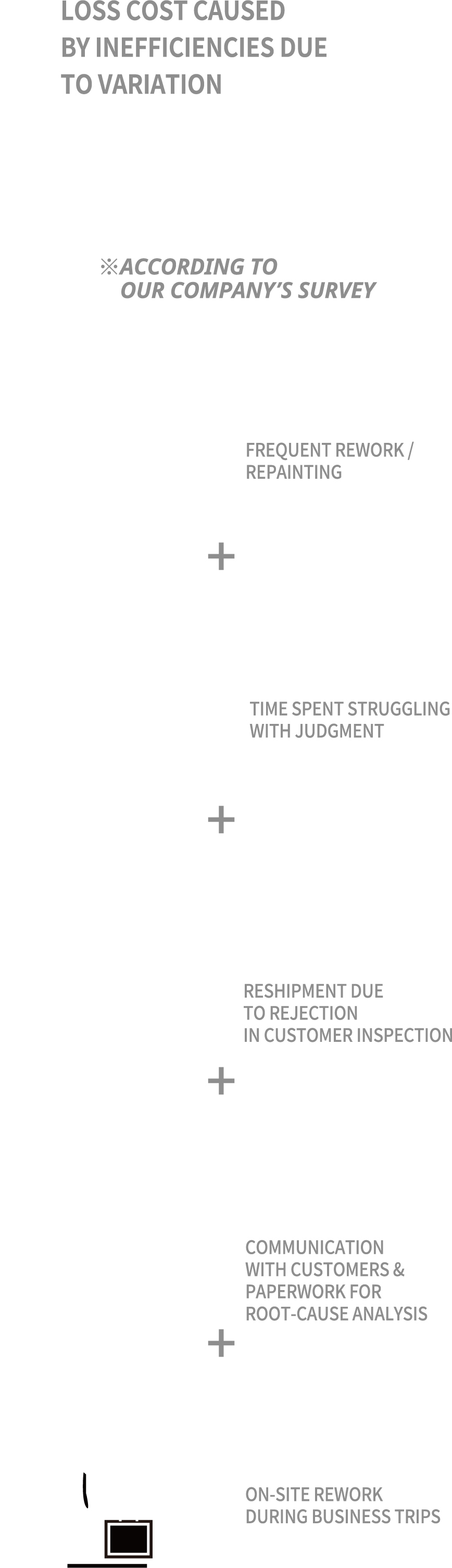

Challenges Facing the Coating Industry

Quality Perception Mismatch

On the supplier side, fear of pass/fail judgments often leads to over-engineering, while lowering standards raises concerns about defects.

On the customer side, decision-makers face the burden of supplier selection, along with increased costs from over-quality and the risk of losing trust due to delivery delays.

Double Checking

Less-experienced inspectors often lack the confidence to make decisions due to fear of overlooking defects.

Even veteran inspectors cannot fully delegate inspections, preventing them from focusing on higher-value tasks.

Seasonal Quality Variation

During peak periods, heavy workloads can lead to less thorough inspections and an increase in overlooked defects.

During slow periods, having more time often results in excessive inspections, driving up costs due to over-quality.

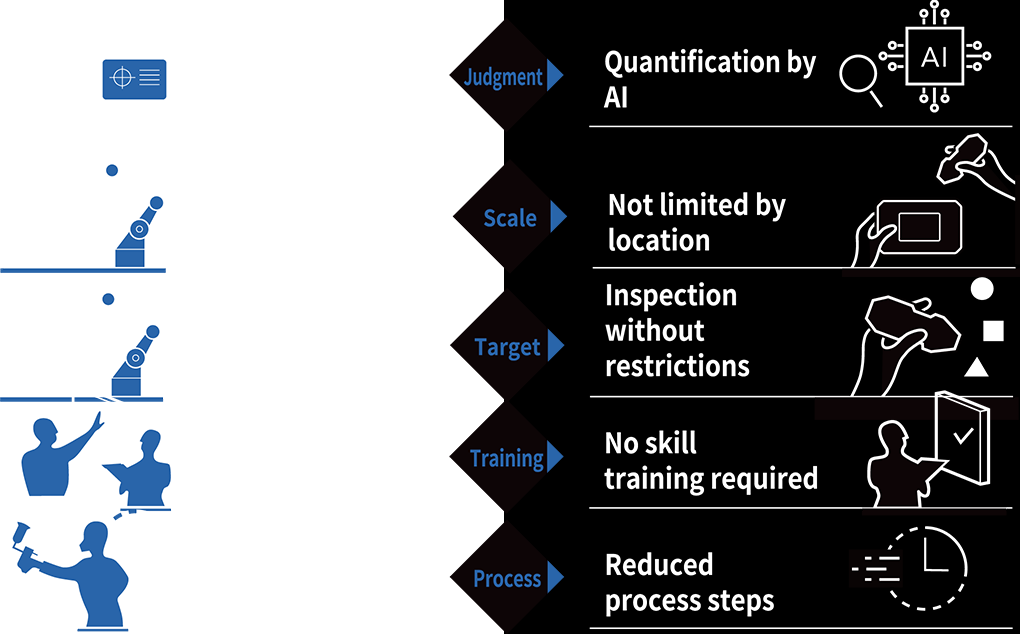

AIN SOLUTIONS’ Solution for Paint Inspection

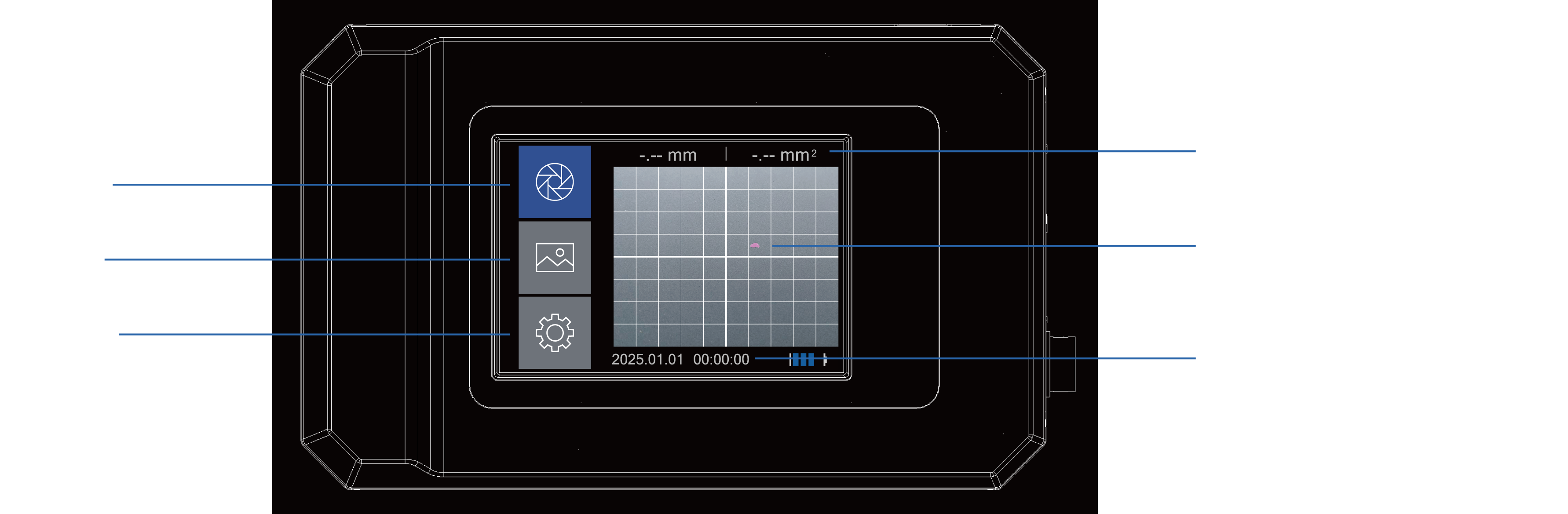

Handheld Type No Restrictions on Inspection Location

An intuitive, easy-to-use interface that anyone can operate with ease.

An ergonomic grip design that is easy to hold and helps prevent slipping,

ensuring stability and comfortable one-handed operation.

The shutter can be operated via

the slide switch on the camera or directly from the monitor interface.

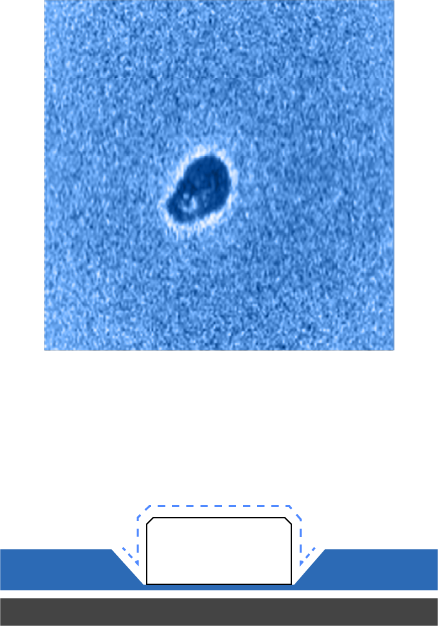

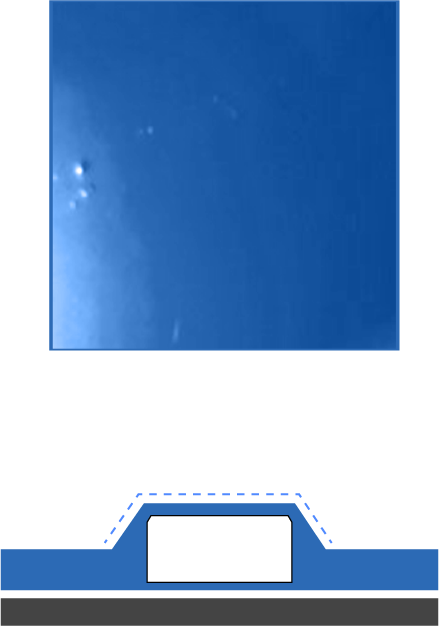

Measurable Targets Enlarged Detection of Dust and Foreign Particles

If you need to inspect or measure specific types of dust or foreign matter unique to your application, AI customization is available upon consultation.

Process Optimization A Rework-Free Workflow

Improved Cost Effectiveness Reduced Costs